1.0 Introduction

The best way to reduce machine powertrain cost per hour is to maximize component life and utilize all of the value built into the component. Avoiding premature component failure is essential to maximizing component life. There are many variables that contribute to premature component failure. One of those variables is corrosion damage of highly loaded precision components, such as bearings or fuel injectors.

Bearings are susceptible to corrosion damage from water in lube oils, and fuel injectors may be damaged by excess water in fuel. Keeping moisture out of bulk fluids is essential to prevent damage to machine components.

The use of desiccant breathers on bulk fluid storage tanks prevents atmospheric moisture from entering the tank and contaminating the fluid. Also preventing atmospheric moisture from entering bulk fluid storage tanks during normal fill and drain cycles will prevent failures due to corrosion. These practices will help extend component life, reduce cost per hour, and improve machine availability.

2.0 Best Practice Description

Many bulk fluid storage tanks at dealer and customer facilities have breathers with unfiltered tank vents. This allows both airborne dirt and moisture to enter the tank and contaminate the fluid. This can be easily corrected by installing desiccant breather filters to the tank vent. Desiccant breathers come in a wide variety of sizes and arrangements. The most common is a disposable spin-on unit that changes color as the desiccant capability is depleted. This allows for easy visual inspection to determine if the unit is functional or requires replacement.

Filter sizing is determined by:

• The maximum flow rate of air into or out of the tanks during usage or refill.

• The pipe or fitting size of the vent pipe where the breather will be attached.

3.0 Implementation Steps

Desiccant breathers are not available through the Caterpillar parts system. They are available from several outside suppliers. Two of the most common suppliers are Des-Case and Parker Hannifin.

The use of desiccant breathers should not be limited to very large tanks. Any size storage vessel, down to barrels, can introduce contamination. Desiccant breathers are recommended for any storage vessel equipped with a breather vent.

4.0 Benefits

Many dealer facilities with modern bulk fluid handling have incorporated desiccant breather filters. The actual incremental benefit is difficult to measure without a baseline of moisture and particulate contamination before the desiccant filtration was installed. However, if stored fluid is found to be contaminated with dirt or moisture, the presence of properly working desiccant breathers indicates the contamination was present in the fluid before delivery.

Operations that have endorsed the usage of desiccant breathers:

• Finning Chile Antofagasta Component Rebuild Center

• Finning Argentina – Alumbrera Mine

• Ferryros Peru – Yanococha Mine

• Western States Equipment – Simplot Smoky Canyon Mine

5.0 Resources Required

Initial installation or fitting of filters to existing vent pipes typically runs from $100 - $500 US. Cost of replacement filters range from $30 for small filters used on barrels and small tanks up to $800 for very large filters used on large bulk storage tanks.

6.0 Supporting Attachments / References

None

7.0 Related Best Practices

0806-2.1-1000 - Fluid Cleanliness Management

0806-2.1-1002 - Off-Board Machine Filtration

0806-2.1-1004 - Breather Filters

0806-2.1-1005 - Bulk Oil Filtration

0806-2.1-1006 - Bulk Fuel Filtration

8.0 Acknowledgments

This Best Practice was written by:

Richard Douglas

CGM Product Support

Douglas_richard_d@cat.com

(309 675-5699

Other contributors include:

Dave Baumann

MPSD Contamination Control

Baumann_david_l@cat.com

(309) 675-6849

Carmen Rose

MPSD Contamination Control

Rose_carmen_l@cat.com

(309) 675-8074

Kiwi Haig

CGM LACD Product Support

Haig_kevin@cat.com

+56 55 200947

|

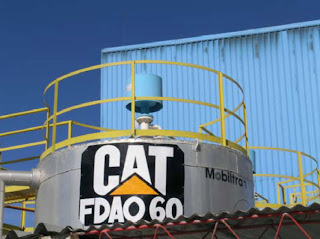

| A desiccant breather on a bulk oil tank |

Bearings are susceptible to corrosion damage from water in lube oils, and fuel injectors may be damaged by excess water in fuel. Keeping moisture out of bulk fluids is essential to prevent damage to machine components.

The use of desiccant breathers on bulk fluid storage tanks prevents atmospheric moisture from entering the tank and contaminating the fluid. Also preventing atmospheric moisture from entering bulk fluid storage tanks during normal fill and drain cycles will prevent failures due to corrosion. These practices will help extend component life, reduce cost per hour, and improve machine availability.

2.0 Best Practice Description

|

| A desiccant breather beginning to change color |

• The maximum flow rate of air into or out of the tanks during usage or refill.

• The pipe or fitting size of the vent pipe where the breather will be attached.

3.0 Implementation Steps

Desiccant breathers are not available through the Caterpillar parts system. They are available from several outside suppliers. Two of the most common suppliers are Des-Case and Parker Hannifin.

The use of desiccant breathers should not be limited to very large tanks. Any size storage vessel, down to barrels, can introduce contamination. Desiccant breathers are recommended for any storage vessel equipped with a breather vent.

4.0 Benefits

Many dealer facilities with modern bulk fluid handling have incorporated desiccant breather filters. The actual incremental benefit is difficult to measure without a baseline of moisture and particulate contamination before the desiccant filtration was installed. However, if stored fluid is found to be contaminated with dirt or moisture, the presence of properly working desiccant breathers indicates the contamination was present in the fluid before delivery.

Operations that have endorsed the usage of desiccant breathers:

• Finning Chile Antofagasta Component Rebuild Center

• Finning Argentina – Alumbrera Mine

• Ferryros Peru – Yanococha Mine

• Western States Equipment – Simplot Smoky Canyon Mine

5.0 Resources Required

Initial installation or fitting of filters to existing vent pipes typically runs from $100 - $500 US. Cost of replacement filters range from $30 for small filters used on barrels and small tanks up to $800 for very large filters used on large bulk storage tanks.

6.0 Supporting Attachments / References

None

7.0 Related Best Practices

0806-2.1-1000 - Fluid Cleanliness Management

0806-2.1-1002 - Off-Board Machine Filtration

0806-2.1-1004 - Breather Filters

0806-2.1-1005 - Bulk Oil Filtration

0806-2.1-1006 - Bulk Fuel Filtration

8.0 Acknowledgments

This Best Practice was written by:

Richard Douglas

CGM Product Support

Douglas_richard_d@cat.com

(309 675-5699

Other contributors include:

Dave Baumann

MPSD Contamination Control

Baumann_david_l@cat.com

(309) 675-6849

Carmen Rose

MPSD Contamination Control

Rose_carmen_l@cat.com

(309) 675-8074

Kiwi Haig

CGM LACD Product Support

Haig_kevin@cat.com

+56 55 200947

I’ll bookmark your blog and check again here frequently. I am rather sure I’ll learn many new stuff

ReplyDelete-

breather plug | breather plugs | breather vent plug

Excellent post. I was always checking this blog, and I’m impressed! Extremely useful info specially the desiccant pouch, I care for such information a lot. I was exploring this particular info for a long time. Thanks to this blog my exploration has ended. desiccant Pouch

ReplyDelete